Acif Kauri | Porcelain Tile

Kauri is an Italian glazed porcelain which uses inkjet capabilities to create the look of petrified wood in three finishes. The bark is a rough, textured finish to represent the outside of the tree, while the Natural (matte) and Lappato (semi-polished) finishes both represent the inside core of the tree. There is separate graphic development for the Bark finish that is different from the other two finishes. All sizes are rectified with the Lappato being rectified a second time to a smaller size after polishing. Expect a lot of variation within each color.

Colors, Size & Trim

| Colors | ||

|---|---|---|

| AFKIBE | Beige | |

| AFKIGY | Grey | |

| AFKIWE | White | Size & Finishes - Rectified |

| 12 x 24 | ||

| AFKI--B/1224 | Bark (Rough) | |

| AFKI--N/1224 | Natural (Matte w/ slight surface undulation) | |

| AFKI--L/1224 | Lappato (Semi-polished) | |

| Trim | ||

| AFKI--B/SBN | 3 x 24 Surface Bullnose-Bark | |

| AFKI--N/SBN | 3 x 24 Surface Bullnose-Nat. | |

| AFKI--L/SBN | 3 x 24 Surface Bullnose-Lap. | |

Additional Information

Using inkjet technology, the Bark with its rough textured finish represents the outside of the tree, while the Natural and Lappato finishes both represent the core of the tree. Acif uses a separate graphic development for the Bark finish that is different from the graphic on the other two finishes.

Finishes

Lappato is rectified a second time to a smaller size after polishing.

Trim

Surface bullnose is made from field that is cut, rounded and reglazed.

Usage

Acif certifies that Kauri is suitable for residential and commercial use.

Installation

Most Italian manufacturers recommend a maximum offset of 8” (20cm) on all large format tiles when setting running bond. Please refer to ANSI requirements for setting large format tiles (ANSI A108.02 Section 4.3.8).

Non-Stock

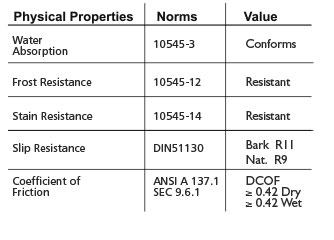

As noted in the American with Disabilities Act (ADA) the coefficient of friction varies considerably due to facts not under the control of entities such as the manufacturers and distributors. These factors include, but are not limited to, contaminants, slope of terrain, drainage conditions, adjacent surfaces, etc. Suitability for any installation can only be determined by a site examination of all conditions that could affect the slip resistance of the tile being installed. Continual cleaning and maintenance must be performed once the tile has been installed.