Natucer Shapes | Spanish Porcelain Tile

From Natucer in Spain, this high quality, extruded porcelain product is made from wet clay and has a handcrafted look and feel. The variation in size and surface texture is an inherent and desirable characteristic of this specialized production method and adds to the appeal of this tile. With a long rectangle, a classic Hexagon and the hot Chevro, Shapes offers endless design possibilities for both modern and traditional tastes.

London White

Oslo Charcoal

Colors, Sizes & Trim

| Colors | ||

|---|---|---|

| NRSHLW | London White | |

| NRSHOC | Oslo Charcoal | |

| Sizes - Non-Rectified | ||

| NRSH--/414 | 3½ x 14* | |

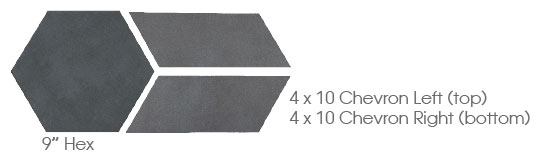

| NRSH--/9HX | 9” Hex | |

| NRSH--/410CNR | 4 x 10 Chevron Right | |

| NRSH--/410CNL | 4 x 10 Chevron Left | |

| Trim | ||

| NRSH--/112SBN | ½ x 12 Surface Bullnose | |

Additional Information

Sizes

Trim

Expect variation in color and size between field and trims.

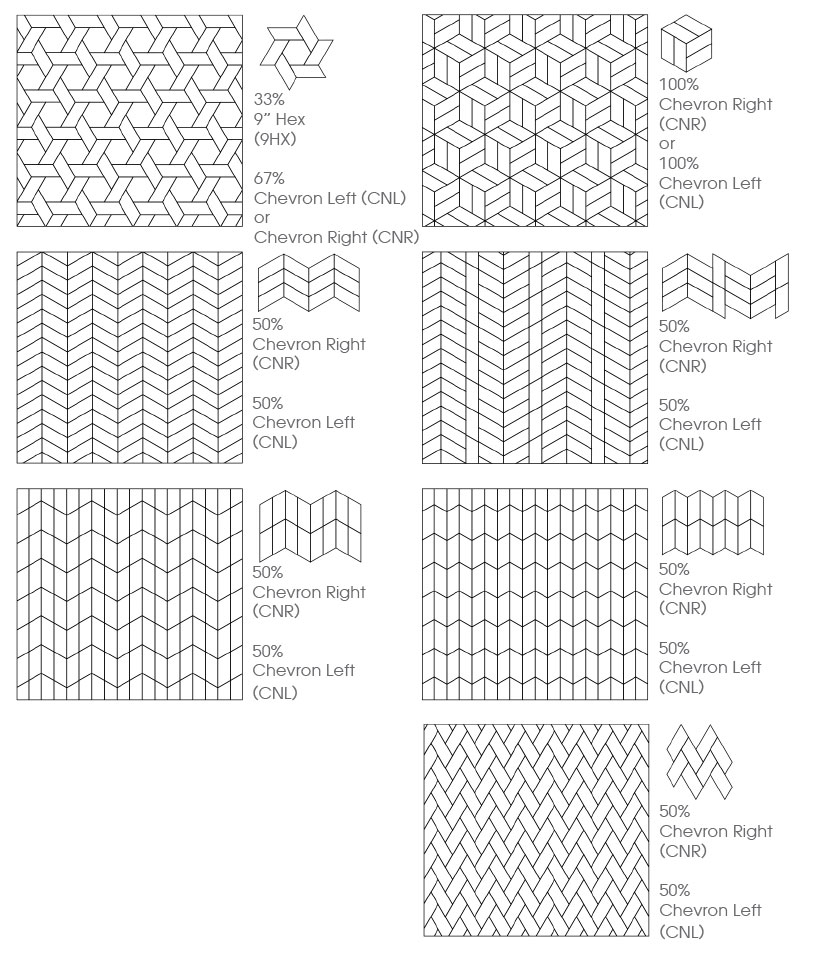

Pattern

Usage & Installation

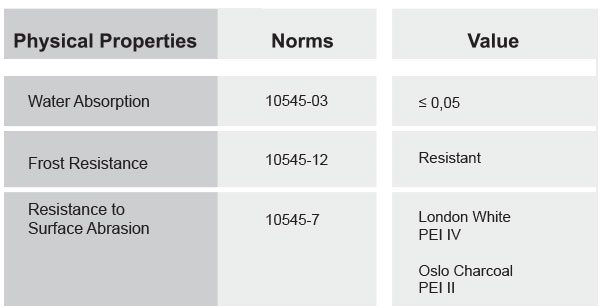

Shapes is suitable for walls and residential floors. The London White color may be suitable for light commercial floors. It is advisable to blend from multiple boxes during installation.

Due to the extruded process that creates this handcrafted look, we recommend using at least an 1/8” grout joint. Please note that, as with handmade products, the tiles may be slightly different sizes and shapes, so you may need to adjust the size of the grout joints, making some a little bigger and some a little smaller, to accommodate these differences. This is especially true when using different shapes together in a pattern, as the edges may not align in perfectly parallel lines that will work with spacers. It is also recommended to use a grout color similar to the color of the tile and to avoid contrasting grouts. It is important to mix pieces within each carton and from several cartons to attain a proper blend. Expect variation from production run to production run, and between the different shapes/sizes.

*As part of the intended, handmade feel of the 3 1/2 x 14, the edges are more cushioned than the other shapes. It is important to wash down the grout to reveal the cushion. Because of the cushion, the grout joint will appear bigger than the spacing between tiles, even when properly washed down.

As noted in the American with Disabilities Act (ADA) the coefficient of friction varies considerably due to facts not under the control of entities such as the manufacturers and distributors. These factors include, but are not limited to, contaminants, slope of terrain, drainage conditions, adjacent surfaces, etc. Suitability for any installation can only be determined by a site examination of all conditions that could affect the slip resistance of the tile being installed. Continual cleaning and maintenance must be performed once the tile has been installed.